CONTATTACI

INDIRIZZO

SOCIAL

Via del lavoro, 39

20052 | Vignate MI | Italia

P.Iva 05876390153

FORIND AVIO ELETTRONICA© 2022 | Tutti i diritti riservati

Cold working technology for fatigue life improvement

Fatigue Technology (FTI) is the world leader in Cold Expansion technologies.

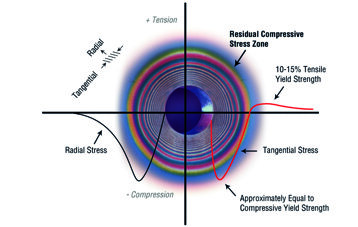

The original cold expansion (cold working) is a process applied to holes in metals that induces a beneficial zone of residual compressive stress around them. The process radially expands the hole at room temperature, typically using a tapered expansion mandrel pulled through the hole, which yields the surrounding material. The resultant reactive force leaves a large zone of residual compressive stress around the hole. This compressive stress zone shields the hole from the effects of cyclic tensile loads which causes fatigue cracks. FTI pioneered this technology with the Boeing Company in the 1960’s and continues to work with industry partners to adapt and optimize the cold expansion process for today’s new aerospace materials and structural requirements.

All of FTI products are based on our Cold Expansion technology. Our engineers have advanced this science to develop innovative expanded fastener, bushing, and fitting products for metal, composite, and hybrid structures. These products are specifically engineered to provide cost savings for structural optimization, manufacturing and maintenance time-savings, and improved aircraft structural performance.”

FTI Fatigue Technology provides a complete line of Fatigue Technology (FTI) cold expansion equipment.

Please contact Forind Avio' sales to obtain the most current Expanded Products Specification for your custom application(s).

TukLoc, the first mechanically secured blind fastener system for use in primary and secondary structures, utilizes a blind nut installed into the structure using FTI's state-of-the-art cold expansion process. TukLoc is installed into the structure by radially expanding the fastener into the hole.

The ForceMate system provides an alternative to heat shrink or press fit bushing installation methods. Use of the system results in consistent installation of high interference fit bushings and improved fatigue performance at reduced installation costs.

FTI's Split Sleeve Cold Expansion™ system is a cost-effective solution to the problems associated with fatigue cracking in holes in metal structures.

ForceTec is a unique method of installing an innovative and cost-effective rivetless nut plate. Unlike traditional riveted or pressed nut plates, the ForceTec system radially expands a retainer in a hole.

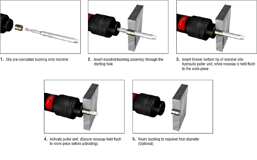

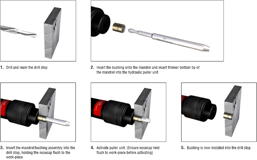

Procedura d'installazione: di seguito sono riportati i passaggi fondamentali del sistema di espansione a freddo a maniche divise.

Designed to avoid delamination problems, ForceTec Modular allows for quick installation and ensures excellent sealing properties without the use of sealants.

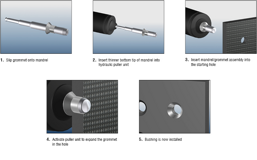

Installation Procedure: TukLoc is installed into the structure by radially expanding the fastener into the hole. This process can be easily used in many blind fastening areas and is an excellent replacement for elliptical press nuts and RivNuts.

Installation Procedure: The ForceMate system includes integrated technology and tools, including ForceMate inserts, mandrels, tips, gauges, support assemblies, cutting tools, extraction units, special fixtures and training. The process is secured by the use of the complete FTI ForceMate system.

Installation Procedure: ForceTec Rivetless Threaded Plates can be installed using a split sleeve, mandrel only, or the AIM system.

The RailTec system was developed for the rail industry and is based on FTI's split sleeve cold expansion system. The flexibility of the system allows it to be easily applied to all tracks on the main or branch line as part of routine maintenance.

StopCrackEX is based on FTI's cold expansion system and products used by all commercial and military aircraft manufacturers to extend the life of holes in metal structures.

The GromEx system is a method of reinforcing fixing holes in composite materials using a thin metal sleeve.

FTI's FleXmate Advanced Aerospace Fitting process is a system for installing hardware.

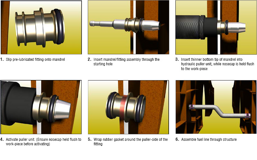

Installation Procedure: FleXmate uses all the same PowerPaks and extraction units as other cold expansion processes.

Installation Procedure: GromEx is versatile and can be used with various standard NAS or other types of mounting devices.

Installation procedure:

Installation Procedure: The installation of RailTec is similar to the standard FTI split sleeve cold expansion process.

Cold Expansion

Di seguito è riportata una presentazione panoramica dell'Espansione a Freddo.

CONTACT US

OUR HEADQUARTERS

SOCIAL

Via del lavoro, 39

20052 | Vignate MI | Italy

P.Iva 05876390153

FORIND AVIO ELETTRONICA© 2022 | All rights reserved